Health and Safety in Business

It is very likely that owners and managers of many smaller businesses are not aware of just how demanding health and safety regulations can be.

We provide an overview of these below and highlight some practical tips and processes on how your business can remain (or become!) compliant.

Legislation governing health and safety

The main statutes are:

- The Health and Safety at Work 1974 (HSWA)

- The Management of Health and Safety at Work Regulations 1999 (Risk Assessment)

- Regulatory Reform (Fire Safety) Order 2005

- The Health and Safety (Consultation with Employees) Regulations 1996

- Safety Representatives and Safety Committee Regulations 1977

- Corporate Manslaughter and Corporate Homicide Act 2007

There are many other regulations relating to specific areas of health and safety, for example, manual handling, safety signs, employment of children, display screen equipment, control of substances hazardous to health, reporting of incidents, control of noise and first aid. There are also approved codes of practice (ACOPS) which provide practical advice on compliance and have special legal status.

Minimum requirements

A business with at least five employees must have all of the following in place to avoid problems with a health and safety inspector:

- a written health and safety policy, which should be specifically tailored for the employer

- assessments of risks from workplace activities

- records of any significant findings from such assessments

- consultations with employees or their representatives on health and safety matters

- health and safety training programmes

- employer’s liability insurance, evidence of which is on display

- health and safety posters on display

- a competent person appointed to assist with health and safety responsibilities.

Sanctions for Non-Compliance

If inspectors arrive from either the Health and Safety Executive (the HSE is responsible for factories, farms and building sites) or the local authority (responsible for offices, shops, hotels and catering) and find a business in breach of health and safety regulations there are a number of types of enforcement action they can take, in increasing order of severity, as follows:

- offer advice, either face to face or in writing

- issue a warning, highlighting a failure to comply with the law

- serve an improvement notice

- withdraw approvals to undertake certain activities

- vary licensing conditions or exemptions

- issue formal cautions (a formal statement of an offence having been committed, acknowledged by the recipient)

- serve a prohibition notice (to stop activities in order to prevent serious personal injury)

- rosecute at the magistrates or Crown Court. This may lead to fines from £5,000 up to a maximum of £20,000 in the lower courts and unlimited fines in the Crown Court and/or up to 2 years imprisonment.

At the same time employees may take civil actions against their employer if they suffer injury or illness and the employer has breached the Management of Health and Safety at Work Regulations 1999.

Why managing health and safety makes sense

In addition to avoiding legal sanction, statistics in 2010/11 show:

- 1.2 million working people were suffering from a work-related illness.

- 175 workers killed at work .

- 115,000

- injuries were reported under RIDDOR .

- 200,000 reportable injuries (over 3 day absence) occurred (LFS).

- 26.4 million working days were lost

- due to work-related illness and workplace injury.

- Workplace injuries and ill health (excluding cancer) cost society an estimated £14 billion (in 2009/10)

Accidents and ill health can be very damaging to business because, in addition to personal injury claims and the direct costs, productivity can be severely compromised. The less visible costs are many and varied and include increased overtime working and temporary labour, stress and more staff absence, production delays, repairs to equipment, costs of management time, customer dissatisfaction and loss.

These are compelling reasons why it makes sense to manage health and safety proactively.

Five-step process to managing health and safety

The HSE has produced ‘Successful health and safety management’ (HSG65) which is an excellent guide on how to plan for and audit health and safety. It suggests a five-step process as set out below.

Step 1

Set your policy. This demonstrates to staff that you take health and safety issues seriously, have identified the risks associated within your business, have assessed those risks and will continue to eliminate or control them.

Step 2

Organise your staff. The effectiveness of your policy depends upon the involvement and commitment of your staff.

Step 3

Plan and set standards. This involves setting health and safety objectives, identifying hazards, assessing risks and implementing standards of performance.

Step 4

Measure your performance. This is about looking at whether your assessments are showing an improvement or the same issues are repeating themselves. Regular inspections and checks should be made to ensure your standards are being met.

Step 5

Learn from experience. If things have gone wrong, this is about reviewing how effective your procedures are and then making changes to improve the effectiveness of these policies and procedures.

Practical tips

The following are some practical actions you could and should be taking today:

- removing items from the work area such as cables and other loose items, which can cause tripping and slipping accidents

- repairing torn carpets and broken edges on staircases to avoid the risk of serious falls

- making sure that workstations are stable, don’t give off a reflective glare and ensuring there is suitable seating and hand and foot-rests so that staff maintain good posture whilst working

- insisting that staff take regular breaks, particularly if working for long stretches at a VDU screen

- undertaking regular fire drills and ensuring first aid training is updated regularly

- keeping the first aid box(es) fully stocked and readily available

- ensuring that health and safety signs are kept relevant and up to date, including the display of non-smoking signs at each staff entrance

- setting up a system to regularly check all electrical appliances and fire extinguishers

- ensuring that staff are aware of the potential risks of performing certain tasks and checking that they are fit to undertake those tasks or know how to do them safely.

How we can help

Health and safety is an important, if not sometimes neglected, area. To help you meet your responsibilities we have provided a simple checklist that you may wish to complete to identify areas within your business that need attention.

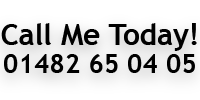

Please contact us if you would like any additional information.

HEALTH AND SAFETY CHECKLIST

If not already in place, the following are practical steps you should take today:

UNDERTAKEN BY: ______________________________ DATE: / /

| Yes | No | |

| 1 Is an Employer’s Liability Insurance Certificate displayed? | ||

| 2 Is a Health and Safety Poster displayed? | ||

| 3 Have all outstanding tasks from previous risk assessments been completed? | ||

| 4 Are there sufficient Fire Marshalls? | ||

| 5 Are there sufficient Fire Action Notices displayed to inform staff of the procedures to take in the event of a fire? | ||

| 6 Are all new recruits advised of the Health and Safety procedures? | ||

| 7 Is the fire alarm tested regularly? | ||

| 8 When was it last tested and by whom? | ||

| 9 When were the fire extinguishers last tested? | ||

| 10 Is the first aid box complete and available to all staff? | ||

| 11 Are there sufficient trained first aiders? | ||

| 12 Is there an accident book and is it being used? | ||

| 13 When was the last time portable electrical equipment was tested by an electrician? | ||

| 14 Is the electrical equipment labelled and dated with the test? | ||

| 15 Have risk assessments of display equipment been undertaken within the last 12 months? | ||

| 16 Is everyone aware of their right to free eye tests? | ||

| 17 Are all items of mechanical cutting equipment adequately guarded (shredders, guillotines etc.)? | ||

| 18 Are filing cabinets where more than one drawer can be opened at a time bolted down? | ||

| 19 Have staff been advised to take precautions when changing toner cartridges? | ||

| 20 Are trolleys etc. provided to assist in the manual handling of loads? | ||

| 21 Are heavy, frequently used items stored on waist level shelves? | ||

| 22 Are steps available for reaching items stored at height? | ||

| 23 Is lighting adequate and in good working order? | ||

| 24 Is there a suitably marked drinking water supply available? | ||

| 25 Are passage ways clear of tripping hazards eg cables, boxes, rubbish etc.? | ||

| 26 Are the tops of cabinets clear of heavy items that could fall? | ||

| 27 Are all entrances and exits in good working order (no grease, broken slabs, poor lighting etc.)? |